Koppel HOn30 Steam Engines

These BCH engines were first produced by the German firm, EGGER-BAHN. EGGER-BAHN was the first company to manufacture a narrow gauge railway in HO (1:87) scale that ran on 9mm gauge track. This combination is HOn30 for an actual gauge of 2 ½ feet (30 inches) or in Europe, HOe for an actual gauge of 750 mm.

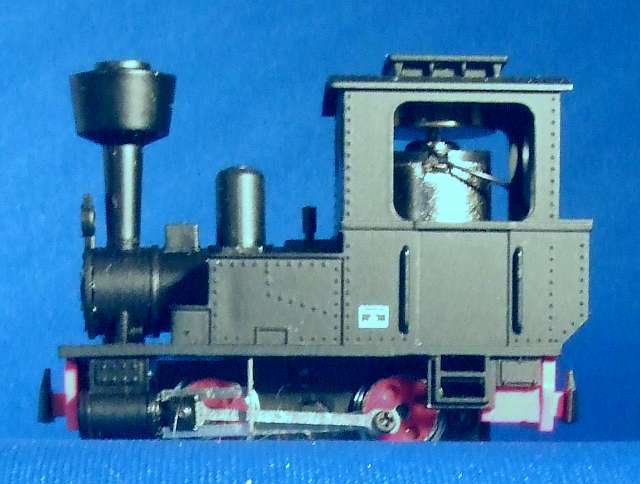

Here are two versions of the early production engines. Note the valve gear is metal or plastic. The vertically mounted open frame motor is clearly visible through the open cab windows.

The BCH MinitrainS Koppel 0-4-0 straight and balloon stack tank engines retain the EGGER-BAHN superstructure and are made with the metal valve gear. Under the boiler there is a “state-of-the-art” mechanism with an all new power train. The Koppel is now made with an enclosed motor and the new motor has a brass flywheel! In addition to the flywheel motor the engine has a split frame to improve electrical pick up from the track. The BCH model of a German Orenstein & Koppel locomotive is a good running engine.

If these Koppel engines are not suitable to run looking as they do, the cab and details can be Americanized. Articles have been written on two Americanization conversions. The first by Mike Pearsall appeared in Model Railroader in the July 1965 issue! Yes, HOn30 has been around for at least that long. Magazine article by Mike Pearsall: http://jehubbard.com/hobbies/model_rr_article.htm

The second conversion article is on John Hubbard’s website. John also has the link to the Model Railroader article. John's EGGER-BAHN rework page: http://jehubbard.com/hobbies/egger-bahn_rework.htm

John’s Americanized Koppel.

All of the production Koppel engines (including the new ones by BCH) have the electric motor in plain view for all the world to see.

Railway Models Koppel

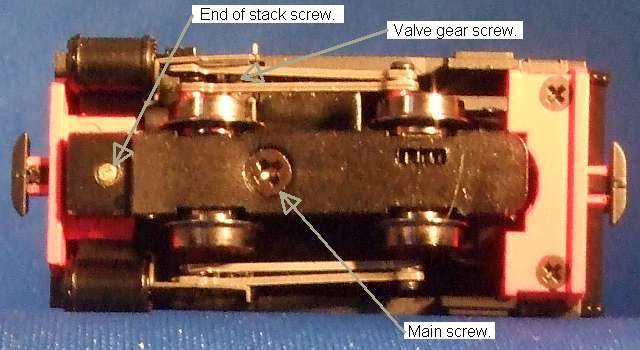

Modifying the boiler and cab requires removing the plastic superstructure from the chassis. Removing the plastic top was nothing with a Plymouth diesel, just lift it off. The job was fairly simple with the Baldwin steamer, one screw through the top of the dome and one screw below the stack. The Koppel steamer is more complicated. The screws are the reverse of the Baldwin.

The smoke stack itself is a screw and must be removed upward using your fingers. Using a tool will leave marks on the plastic. Be careful not to break the headlight which is close to the stack. The other screw is under the engine, easy. Now the fun part. On the Koppel one end of the main rod is attached to the wheels with the cylinder end held in position by valve guides mounted to the boiler. Thus the metal valve guides must be unscrewed from the boiler to allow the boiler to be taken off for conversion. Removing the two guide retaining screws (one on each side) is easy. Replacing these tiny screws while holding everything in the correct place is tricky.

If the main engine appearance problem is the red colored parts, the red plastic pieces on the front and rear of the engine can be easily removed for painting or Micro Trains coupler installation. Unscrewing the stack frees the front piece. Removing two accessible screws under the engine releases the rear. The red wheels could be painted black on an assembled engine with a fine brush.